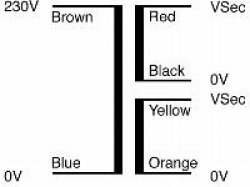

Colour code:

0-230v Blue Brown

0-120v White-Black1st Secondary Black-Red

2nd Secondary Orange-Yellow

Other notes & terms. Power rating

- VA

To calculate VA is Volts x amps = VA

Current = amps VA / Volts=Amps - HP to Watts

Horsepower to Watts

746 watts equals 1 horsepower. - DC

AC to DC multiply ac voltage by 1.41 and current by 1.7

Dc volts to ac volts dcv x .71 - T.P.V Turns per volt

The number of turns required giving one volt.

Turns / volts = tpv - Temperature

All our transformers are designed to run at a max of 50degC above ambient. - Frequency

The mains frequency in the ECC is 50hertz and in the USA 60hertz all our transformers are designed for 50/60hertz. We can design for higher frequency up to 400htz (this will make the transformer small.

With higher frequency transformers wire remains unchanged but core and turns may be significantly smaller (150hz will be one third the size and number of turns) - We cannot step the frequency up or down. This requires a signal generator and amplifier. Almost all-electronic equipment is suitable for 47 to 63htz

- Regulation

This is the power lost (heat) in the normal operation of the transformer. A regulation of 6% means the transformer is 94% efficient - Manufactured to Class A 105degC

- RoHS Compliant

- Class Max Temperature Max Temp Rise

A 105°C 65°C

E 120°C 80°C

B 130°C 90°C

F 155°C 115°C - Losses

Transformer losses do not exceed 2.5watts per kilo (core weight X 2.4) / input voltage - Inrush current

Generally toroidal transformers have a higher switch on surge current which could trip a miniature circuit breaker (MCB), in normal operation. Type 4 or motor rated MCB’s should be used in such situations

Inrush current could be more than 50amp for a few micro seconds.

A surge limiter could be provided see "UPGRADES" Protection - Copper Wire

Enameled copper wire

Enameled copper wire Polyester/Imides Grade 2 180degC thermal Class H BS6811: 3.3 & Sold able Grade 2 155degC Class F BS6811: 3.9

Copper purity: OFC 99.99%

oxygen free copper) - Testing

All our transformers are 100% tested. Airlink record stands for itself with a 0% in-field failure rate and a 0.02% in-house failure at final 100% test. Airlink transformers are reliable, safe and manufactured to the highest of standards.

HI_POT 3000VRMS between primary and secondary - Faraday shield

Electrostatic screen wound between the primary and secondary - EMI/RFI Shield

GOSS steel band (2 layers) - Leakage

Leakage current: Nominal 100 micro-amps at 230vac

Notes relating to transformers Standards

BS EN 61558 which is entitled "Safety of power transformers, power supply units and similar” It is the specification most commonly called for these days and replaces older specifications such as BS EN 60742 BS3535 and UL1411

We can however issue a certificate of conformity to all these standards

UL6500 is the latest update and will replace UL1411 the main difference being the humidity test with UL6500 requires a 3850vdc flash test for 60seconds after being in a humidity chamber at 30degC 95% for 48hours

This category covers audio amplifier assemblies, audio equipment chassis, cable-converter and microwave communication equipment chassis, card-cage assemblies, mixer assemblies, power-supply chassis, preamplifier assemblies, radio chassis, television chassis, video recorder chassis, and similar components intended for use in Audio/Video Apparatus

BS EN 61046 is entitled "Specification for DC or AC supplied electronic step-down converters for filament lamps”. This specification may be applicable to the complete equipment but I don’t think it can be applied to just the transformer. The testing of the transformer should be determined by reference to BS EN 61558.

Technical Notes for our Chassis Mounting Autowound Transformers Range

Using an auto-transformer is always an economical solution when you need to step down the voltage from 230V to 120V or vice versa, and the equipment already has a fully isolated transformer or when the components do not require an isolated transformer.

The toroidal construction of an auto-transformer offers important advantages in comparison with an E/I lamination core transformer, like smaller physical size and weight, 30-70% reduction (depending on secondary voltage) and very low magnetic stray fields. The auto-transformer can be mounted horizontally using a steel washer or an epoxy potted center with a mounting hole.

Step up/step down: Auto transformers

With its small size and weight, the auto-transformer can be installed easily in existing equipment or supplied in an enclosure, with or without cord, plug and receptacle.

Input 120V to 240V and

Input 240V to 120V

Input 110V to 415V and

Input 415V to 110V

Input 230V to 415V and

Input 415V to 415V

Transformers are regarded as a component and as such are considered to be EMC benign. There will be a requirement for RFI testing of the complete dimmer rack and the complete equipment should carry the CE mark. I think it is misleading to CE mark the individual components.

Flammability

The lowest spec is UL94HB

HB stands for horizontal burn this allows for some burning and is the lowest possible rating.

UL94V-0 requires some level of self-extinguishing properties (V stands for Vertical burn)

The potting compound PC5449 is rated at UL94V-0

The Nylon66 pillars is rated at UL94V-2

Crimping

Molex KK Range 3.96mm(.156") Pitch

2way to 5way available from stock

Amp Mate-N-Lok

Universal power coupling and power to board connectors 6.35mm (o.25") pitch.

Push to reset Circuit Breakers

Available from 6amp to 45amps (connected through Brown live).

Technical Notes for our Chassis Mounting Standard Transformers Range

Colour code:

0-230v Blue Brown

0-120v White-Black1st Secondary Black-Red

2nd Secondary Orange-Yellow